淘宝旗舰店

登录

注册

退出

淘宝旗舰店

登录

注册

退出

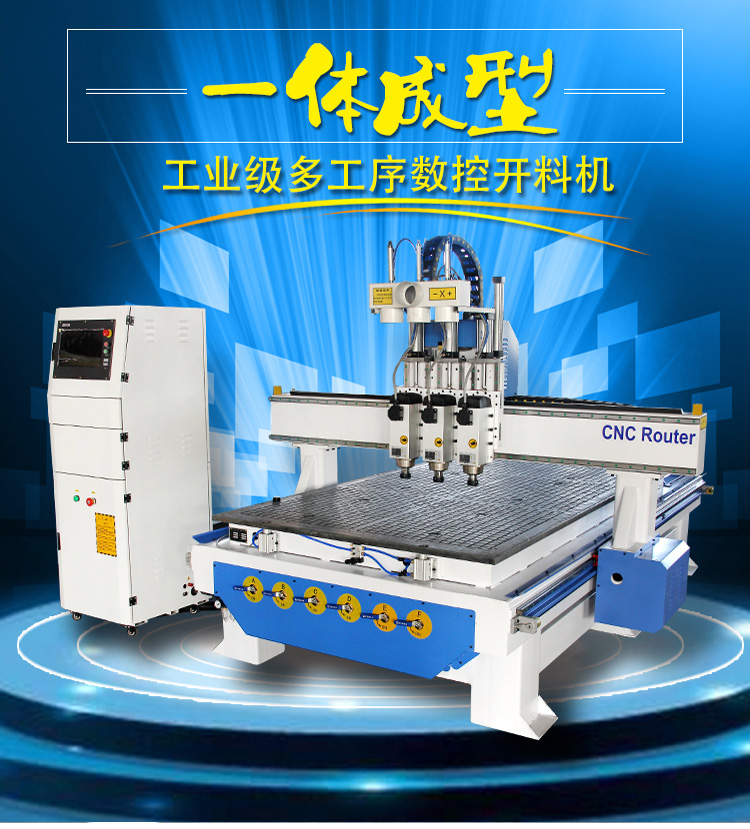

Multi - process material opening machine - three - process CNC engraving machine

We all know that the car is to do regular maintenance, CNC engraving machine is the same.

CNC engraving machine is used in a bad environment, to make the engraving machine components always keep in good condition, the maintenance and maintenance of the machine is essential, pay attention to all aspects of the details can be eliminated in the bud hidden trouble, avoid causing unnecessary losses to the machine. Only regular maintenance can ensure the engraving machine normal service life, or even longer...

One, regularly check the circulation system, oil supply device is normal, cold winter need to be timely replacement of antifreeze, replacement of gasoline engine oil. In severe weather, if the antifreeze fluid is not replaced in time, the water pipe will freeze, and the cooling water will freeze in the main shaft, which will easily cause the main shaft freeze crack; After the weather becomes cold, the oil will become thicker and the oil will flow slowly. If the gasoline engine oil is not replaced in time, the oil supply system will fail.

Two, the use of CNC engraving machine should also pay attention to the temperature of the motorized spindle, always pay attention to the temperature of the motorized spindle, beware of damage to the spindle overheating (note: summer due to the hot weather air temperature is higher, so the temperature of the motorized spindle will be appropriately higher, but as long as the hand can be touched briefly can be normal use). Some carving machine factory spindle is not equipped with circulation cooling system, when the temperature is too high, always pay attention to the temperature of the water tank to increase the new cold water, there is no circulation cooling system of stone carving machine equipment easily cause damage to the motorized spindle, so at the beginning of the purchase must pay attention to sharpen your eyes.

Three, stone carving machine must ensure a good ground, reduce electrostatic interference, improve the stability of the machine and the protection of operators, the rainy day lightning can not be controlled, it is recommended not to run the machine in the thunderstorm weather, and to ensure that the power supply is completely disconnected;

4. Keep the workshop ventilated and check whether there is dripping in the workshop. Although the shape of the carving machine with steel structure or cast iron structure is relatively solid, but water droplets to the carving machine may cause rust damage; At the same time to avoid the work environment is too wet, resulting in the engraving machine distribution box internal electronic components caused short circuit and other unnecessary faults.

5. If the engraving is not used for a long time, the machine should be started up and run in idle regularly to ensure the lubrication of the transmission system. Dust removal regularly, do a good job of dust removal, to avoid dust accumulation affecting the heat dissipation of electrical parts, resulting in burnt short circuit;

Six, the peak power consumption, often appear power supply line voltage instability phenomenon, which in the stone carving machine is often shown in the engraving machine spindle stop phenomenon, low configuration engraving machine will also appear in the drive overload burn off phenomenon. It is suggested that customers must polish their eyes when buying engraving machine and choose a engraving machine with higher configuration to reduce unnecessary losses.

E-Mail: 965617897@qq.com

Hotline: +86-0635-8723128

Mobile/WeChat: +86-18106355053